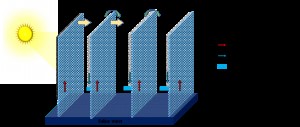

Schematic diagram of a multistage solar thermal desalination system (Image: Nabajit Deka)

Clean, potable water is the need of the hour, but current methods used to desalinate salt water are energy intensive. Researchers from the Department of Mechanical Engineering, Indian Institute of Science, Bangalore, have designed an energy-efficient solar-powered desalination unit.

The most common methods for desalination are membrane-based reverse osmosis (RO) and thermal desalination. Thermal desalination systems work by heating saltwater and then condensing the vapour to obtain fresh water. But the energy required for evaporation is usually obtained from either electricity or the combustion of fossil fuels.

Solar stills are used to evaporate saltwater in large reservoirs wherein the vapour condenses on a transparent roof. However, during condensation, a thin layer of water forms on the roof, which reduces the amount of solar energy that can penetrate the reservoir and thereby reducing the system’s efficiency.

The newly designed unit uses solar thermal energy to evaporate a small volume of water imbibed or “wicked” into the evaporator, which has a textured surface. Taking advantage of the capillary effect of microscale textures, the liquid is drawn into narrow spaces of a porous material, much like water being absorbed by a sponge. Not heating the entire liquid volume in the reservoir increases the efficiency of the system.

Clean, potable water is the need of the hour, but current methods used to desalinate salt water are energy intensive. Researchers from the Department of Mechanical Engineering, Indian Institute of Science, Bangalore, have designed an energy-efficient solar-powered desalination unit.

Experimental setup (Photo: Nabajit Deka)

The energy-efficient and cost-effective desalination unit designed by the IISc team can be conveniently set up in areas with limited access to continuous electricity, explains Susmita Dash, Assistant Professor in the Department of Mechanical Engineering, in a report published by the IISc.

To prevent the formation of the water film during condensation, the system has a fabricated condenser with alternating hydrophilic and superhydrophilic surfaces. The water droplets condensing on the hydrophilic patterns are pulled toward the superhydrophilic region. This enables the hydrophilic surface to become free for a fresh batch of condensate.

Susmita Dash, Nabajit Deka

The setup has been jointly designed by Dash and her PhD student Nabajit Deka. It has a reservoir of saline water, an evaporator, and a condenser enclosed within an insulating chamber to avoid heat losses to the ambient air.

On the surface of the aluminium evaporator, tiny grooves have been etched. The team experimented with different combinations of groove dimension and spacing and surface roughness to determine the right pattern for efficient wicking.

With over 18 percent of the World’s population, but only 4 percent of its water resources, India is among the most water-stressed countries in the world.

The study was conducted with funding support from the Department of Science and Technology, Govt of India. The findings have been published in the journal Desalination of ScienceDirect.

India Science Wire

ISW/SM/IISc/Desalination/Eng/01/06/2023