Droplet breakage leads to undesired spots, reduced resolution in printing, and environmental pollution. Researchers from the Centre for Nano Science and Engineering, Indian Institute of Science, Bangalore have studied the droplet breakage on impact, affecting various day-to-day applications, such as printing, spraying, and coating.

Looking at glossy magazines with beautiful pictures or shiny painted surfaces we hardly realize that they are made up of millions of tiny drops of printing inks or paints. If these drops do not form properly and break while hitting the surface, the quality of the final product gets affected.

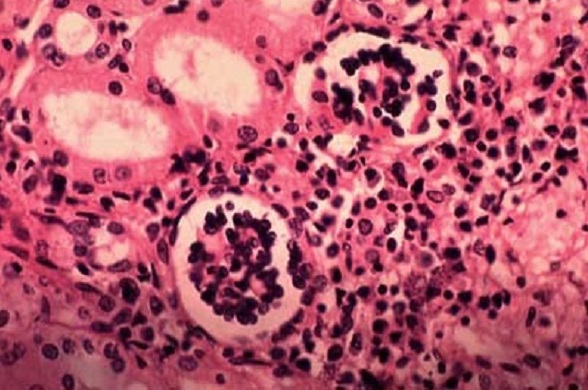

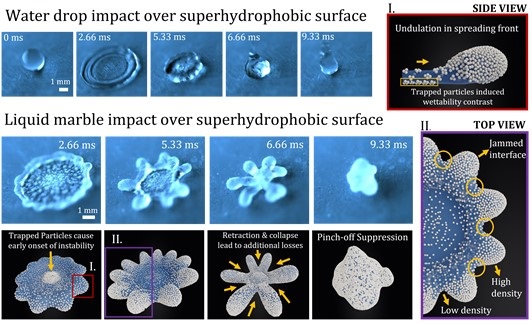

The researchers examined particle-coated droplets and their behavior when impacting superhydrophobic surfaces. They found that when droplets hit a surface, they can break apart, which is suboptimal for applications like printing or spraying. However, by coating droplets with tiny hydrophobic particles, they could prevent them from breaking.

“The coating on particles significantly changes the behaviour of the droplets upon impact. By studying how particle coatings on droplets can change the impact process, we can find ways to prevent droplet breakage and improve these applications,” informs Dr Prosenjit Sen, the lead researcher.

The team aimed to understand how these specialized droplets differ in terms of breakage compared to regular droplets and thereby shedding light on potential applications and benefits.

Droplet breakage leads to undesired spots, reduced resolution in printing, and environmental pollution. Researchers from the Centre for Nano Science and Engineering, Indian Institute of Science, Bangalore have studied the droplet breakage on impact, affecting various day-to-day applications, such as printing, spraying, and coating.

(From left: Rutvik Lathia, Chandantaru Dey Modak, and Prosenjit Sen)

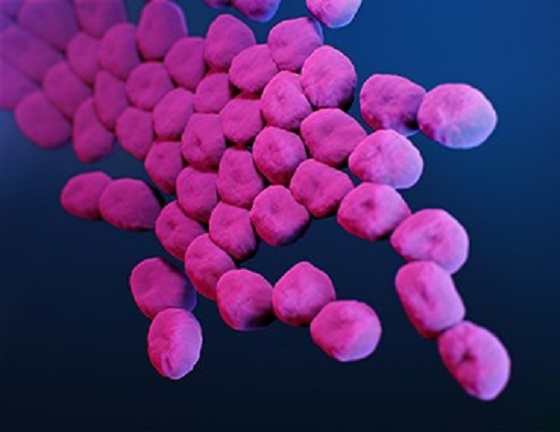

“The findings also have broader implications for self-cleaning surfaces, anti-icing methods, and even the spread of diseases and hence significant practical benefits,” Dr Sen explains.

The coated droplets resisted breaking even when they hit the surface with more force, unlike regular droplets. The team identified a special interfacial instability that occurs early at the surface of the coated droplets. Unlike normal droplets, this instability creates "fingers" on the droplets, making them more stable and less likely to break when they bounce off a surface.

“We also found various physical factors, such as the rim Bond number, surface anomalies, and particle jamming, which help explain why this instability occurs. The presence of these stable fingers reduces the chances of droplet pinch-off during rebound, resulting in more stable droplets,” the researchers mention.

The study has uncovered a fascinating phenomenon involving the induction of interfacial fingering instability, which aids in suppressing breakage in particle-coated droplets. Unlike regular droplets that are prone to breaking upon impact, this instability acts as a protective mechanism, preventing droplet breakage even at higher velocities.

“It's a counterintuitive phenomenon that highlights the remarkable stability conferred by the presence of particles on the droplet's surface,” observes Dr Sen.

The findings also highlight the importance of understanding the dynamics of particle-coated interfaces, which can have implications for fields like bioreactor design, digital microfluidics, self-cleaning technologies, and disease spreading in plants through pollen-laden drops.

In addition to Dr Prosenjit Sen the team comprised Rutvik Lathia and Chandantaru Dey Modak. The study has been published in the Journal of Colloid and Interface Science. It was conducted with financial support from the Department of Science and Technology and the Ministry of Education, Government of India.

India Science Wire

ISW/SM/IISc/droplets/Eng/05/06/2023